More than a Hill of Beans - The History of Food Processing in Indiana

It all started with beans. Pork and beans, to be precise.

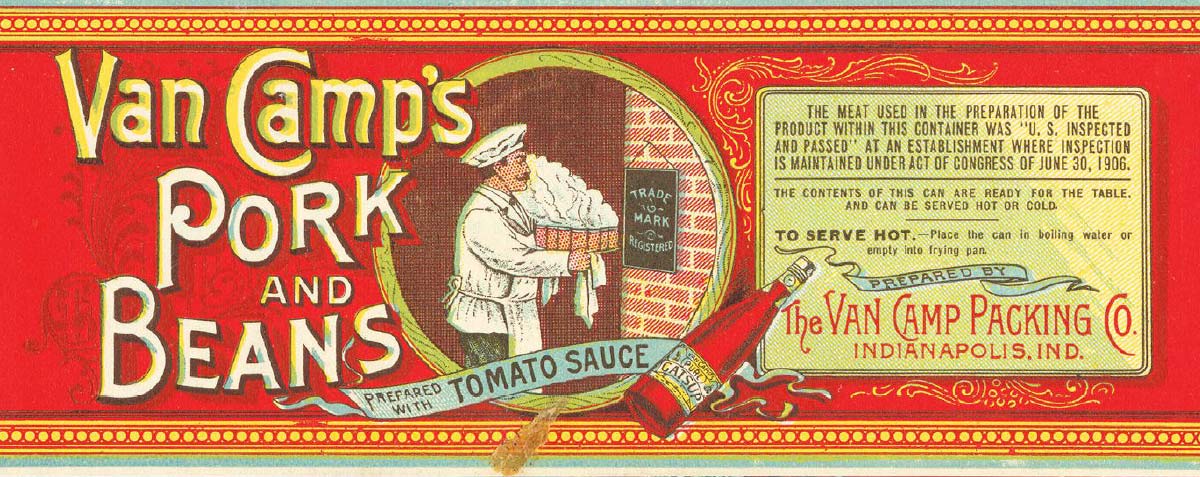

The story of food processing in Indiana is filled with many interesting people and companies, but no telling of it would be complete without including Gilbert Van Camp and his son Frank, who is credited with adding tomato sauce to their pork and bean recipe sometime in the 1890s and putting Indiana on the map for what was previously known as “Boston” baked beans.

Of course the Van Camps had been in the canning business in Indianapolis for decades before their famous bean discovery. According to Clifton J. Phillips in his essay “The Growth of Manufacturing,” Van Camp, along with James T. Polk of Greenwood, were among the first commercial canners in Indiana, beginning their operations on a small scale sometime in the 1860s or 1870s.

Industrialized canning had been at work in the United States since 1812. The Civil War in mid-century, and the demand over many years for battlefield-ready food supplies, gave factory food production its first big nudge. But the decades leading up to and just into the 20th century brought technological advances that propelled the food manufacturing industry into prominence in the U.S., and in Indiana particularly.

First, the discovery of natural gas in 1890 and the subsequent increase of domestic tinplate production made factory operations more affordable. Then, the widespread use of the double-seam tin can around 1904 meant no more soldering and vastly more efficient production lines.

In fact, from 1879 to 1919, the proliferation of canning companies in Indiana increased 2,600%, from just six canneries in 1879 to 166 in 1919. In addition to larger operations in Indianapolis, canneries were opened in dozens of small communities around Indiana, including Boone, Daviess, Delaware, Henry, Howard, Johnson, Madison, Scott, Tipton, Wabash, Washington and Wayne counties. The number of workers increased 12 times over from 337 to 4,170, and the value of products rose from $249,000 to nearly $28 million!

In addition to Van Camp’s pork and beans, Isaac V. Smith of Delphi also developed a technique for canning hominy, an innovation in 1896. And by 1919, Indiana was the national leader in canning pumpkin, hominy, tomato pulp and, of course, baked beans.

STOKELY-VAN CAMP

While the Van Camp family was perfecting their pork and bean recipe, the Stokely brothers, along with their mother Anna, began their own cannery in 1898 to process the surplus produce from their Tennessee farm. Intrigued by the modern canning factories in Indianapolis, one of the brothers, George, headed north around 1909 to learn more. By 1933, the Stokelys worked out a deal to merge with the Van Camps, and in 1944, the company name was officially changed to Stokely-Van Camp, Inc.

With another war at hand, Stokely-Van Camp again leveraged their food production operation to feed the troops. They produced C-rations for the U.S. military consisting of pork and beans, canned meat and candy.

Quaker Oats purchased Stokely-Van Camp in 1983, then in 1995 Quaker Oats sold Van Camp’s famous pork and beans to Conagra, which continues to produce and distribute them today. The Stokely brand was previously sold off to Seneca foods in 1985.

Courtesy of the Indiana Historical Society

Courtesy of the Indiana Historical Society

FALL CREEK CANNING CORPORATION

While the Van Camps were making a name for themselves as the number one canner of baked beans in 1909, Homer Motsinger, a successful Pendleton businessman, was preparing to liquidate all of his assets with plans to relocated to Lafayette. One of his factory buildings, known as the Factory on the Falls, was sold to the Lee Canning Company in 1910.

According to the Indiana State Board of Health’s Eighth Annual Report of the Chemical Division of Laboratory Hygiene, in 1913 the Lee Canning Company produced canned tomato and tomato pulp. They were given a “fair” rating with the following comments: “This company has a brick building and concrete floors, in good condition. Yard toilets are only fairly well kept and no wash rooms are provided. The drain tile carries away the waste matter. Pulp is packed in one gallon tin cans.”

In the same report, an E.R. Lee of Pendleton was also shown to produce legal vinegar, though that may have been part of the same tomato processing business.

The 1915 Indiana State Board of Health Report indicated that the Lee Canning Company was no longer in operation. However, by 1922, Canning Age, a journal devoted to canning, packing and allied industries, announced “For the first time in two years, the Fall Creek Canneries, Pendleton, Indiana, are operating.” Apparently, the cannery was purchased by a new company with plans to reopen operations as early as 1920, when some of the land around the factory was donated for a new city park. According to Jacob Piatt Dunn and General William Harrison Kemper in their book Indiana and Indianans: a history of aboriginal and territorial Indiana and the century of statehood, Pendleton native William Morris Swain was the president of the Fall Creek Canning as of 1919.

Few artifacts remain from the Fall Creek Canning Corporation, but a label for Fall Creek Sweet Peas reveals at least one product of the cannery.

Courtesy of Clabber Girl

Courtesy of Clabber Girl

FARMERS PRIDE

Meanwhile, the Hulman family in Terre Haute introduced the Farmers Pride brand into their wholesale grocery business around 1905. By bringing an experienced chemist onto their staff, they compounded recipes for the best jams, jellies, relishes and preserves over three years of experimentation. In 1911, the brand was extended to include a different kind of bean than the Van Camps were producing: a special blend of coffee beans.

Coffee roasting had been the personal project of company founder Herman Hulman since 1879. When he couldn’t find a high-quality coffee for his grocery wholesale business, he secured a green coffee bean supplier and roasting equipment and forged a business relationship with Jabez Burns & Sons. Hulman & Company began selling their Rex Coffee blend in 1885 and was issued a U.S. trademark in 1905.

Over the years, Hulman & Company sold a variety of products under the Farmers Pride label, including canned fruit, vegetables, tea, coffee, spices, extracts and apple butter. Hulman & Company processed some of the products, and some of the products were produced in other states but sold under Hulman & Company brands.

The Hulman wholesale general merchandise store closed in 1995. However, during a 2009 renovation project of the original Hulman & Company building in downtown Terre Haute, a leather suitcase used by a salesman in the early 1900s was discovered. The contents of that suitcase—coffee samples, sales catalogs and other historical reference materials—were used to help re-create the Rex Original Blend and Farmers Pride Coffee blends.

In fact, coffee is the only product still distributed under the Farmers Pride name today. It is sold exclusively at the Terre Haute Clabber Girl Corporation headquarters, a division of the modern day Hulman & Company.

Working hard to give consumers a better product, Red Gold offers verified non-GMO products and a non-BPA liner.

Courtesy of Red Gold, Inc

RED GOLD, INC.

Nearly half a century after the Hulmans introduced their Farmers Pride coffee, Grover Hutcheson and his daughter, Fran, began processing canned tomatoes and tomato purée to feed the U.S. Army during World War II. Known as the Orestes Canning Company, Grover and Fran began operation in 1942 and invited local farmers to join their venture by planting tomatoes that they could process. Within six years, Fran Hutcheson Reichart and her husband, Ernie, took over the management of the company, and Orestes began selling products under the Indiana Chief and Indiana’s Finest labels.

In 1955, the Orestes Canning Company expanded into a newly acquired plant in nearby Galveston. Then, in 1970, after three decades of steady growth, the Orestes Canning Company purchased the Red Gold label from a cannery in Trafalgar and officially changed their name to Red Gold, Inc. At that point, the company added ketchup and tomato juice to their product offerings.

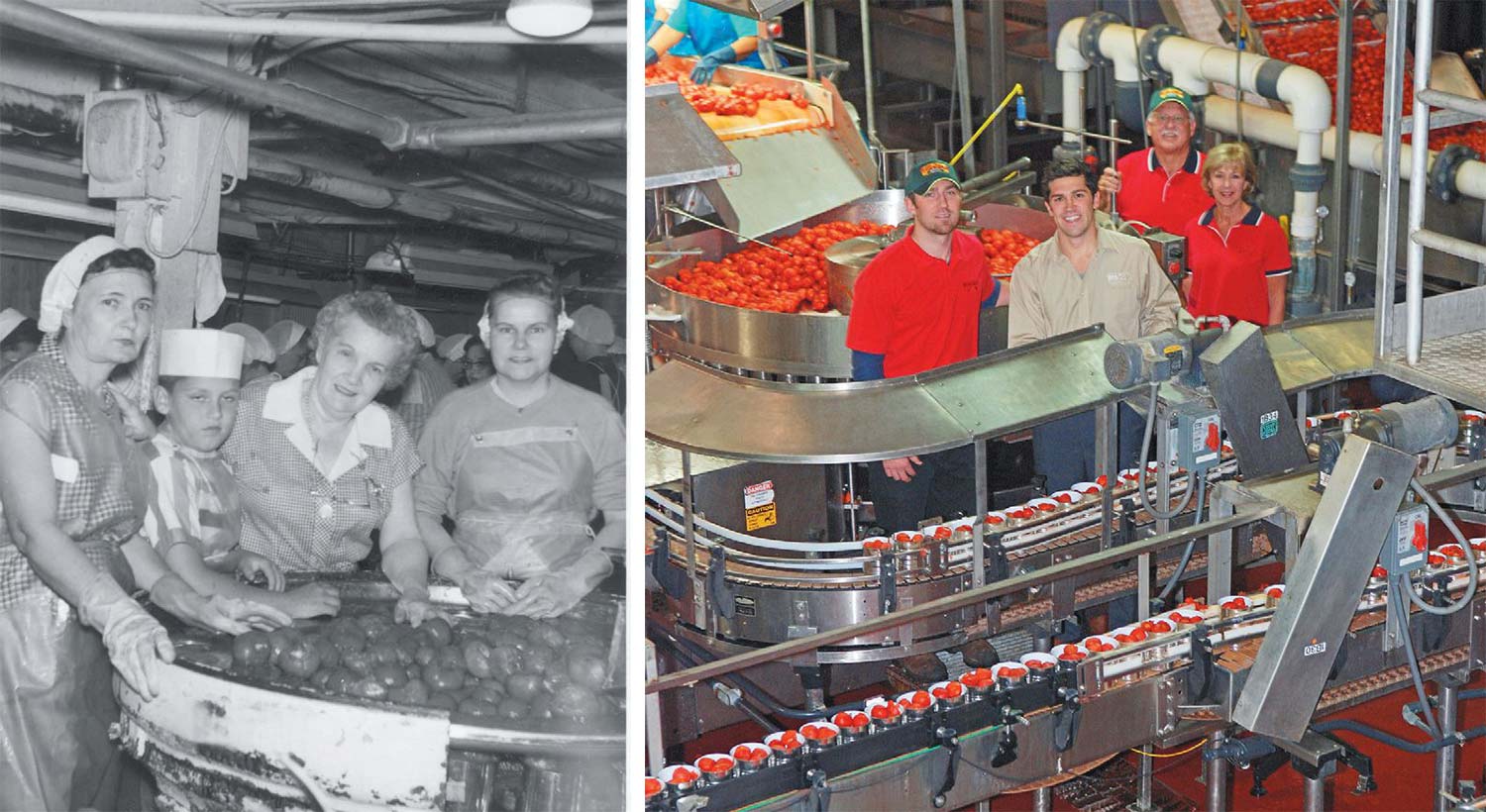

The Reichart kids practically grew up at the cannery their grandfather built, helping out almost as soon as they could walk. As Brian remembers, “When the babysitter didn’t show up, or I just got bored at home, I’d come to the factory and there was always an easy job to start out with.” Courtesy of Red Gold, Inc.

The Reichart kids practically grew up at the cannery their grandfather built, helping out almost as soon as they could walk. As Brian remembers, “When the babysitter didn’t show up, or I just got bored at home, I’d come to the factory and there was always an easy job to start out with.” Courtesy of Red Gold, Inc.

In 1980, the third generation of the Hutcheson family took over leadership of Red Gold when Fran and Ernie’s son, Brian Reichart, became CEO. Under new leadership, Red Gold purchased the former Fettig manufacturing plant in Elwood and expanded its production into food service and contract packaging. Within the year, they also acquired the former Fettig Transport to improve product distribution.

Over the years, Red Gold has acquired several other companies and brands, including the RTS Brands (Redpack, Tuttorosso & Sacramento). Their product line has grown extensively, yet they’ve always remained loyal to the tomato, where the whole Red Gold enterprise began. Whether they are manufacturing Tuttorosso pasta sauce or sriracha ketchup, their products always have tomatoes at their base. In fact, according to their corporate website, Red Gold sells more canned tomato products than any other manufacturer in Chicago, New York and 36 other major U.S. markets and nearly one-third of all canned tomato products purchased in the nation are made by Red Gold.

Interestingly, in 1993, Red Gold purchased the Stokely Brand of tomatoes and their production facility in Paulding, Ohio, which brings us back to the beginning of food processing in Indiana. Turns out canning added up to more than a hill of beans for Indiana. From the Van Camp’s Pork and Beans to Fall Creek Canning Corporation’s Sweet Peas, from the Farmers Pride Coffee to Red Gold tomatoes, food processing has played an important role in putting the Hoosier State on the map.